Maobang: Professional Warehouse Storage Racks Manufacturer

Guangzhou Maobang Storage Equipment Co., Ltd. is one of the earliest warehouse shelving suppliers in mainland China and one of the largest racking system factories in China.

Maobang has strong technical force and product development capabilities, with more than 50 senior technical personnel, more than 20 project implementation engineers, more than 50 professional after-sales teams, a production base of 200 million square meters, and more than 30 automated production lines, which can meet different warehousing logistics planning and design requirements of customers.

Since its establishment, Maobang has adhered to the business philosophy of "integrity, collaboration, sharing, win-win, development" to provide customers with the most professional warehouse shelving systems and designs to help customers upgrade their industries, improve warehouse storage space utilization, and reduce warehousing logistics operating costs, improve management and operation efficiency.

Maobang is committed to the development of warehousing and logistics with the aim of "professional casting quality". We will, as always, provide you with scientific design solutions, with high quality products, dedicated service for you!

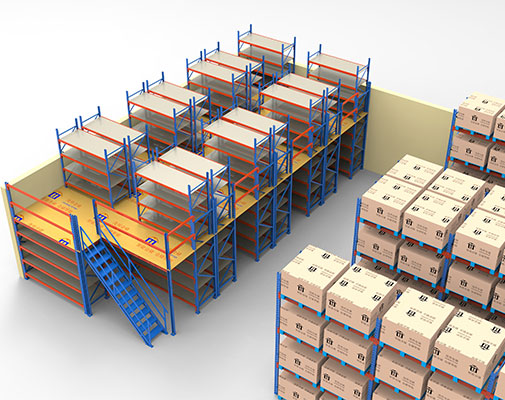

Warehouse Racking and Shelving

Warehouse Storage Solutions

Our company specializes in providing top-quality racking and storage solutions designed to maximize space utilization and organization. We offer a wide range of racking and storage solutions tailored to meet your specific warehouse needs. Whether you require heavy-duty pallet racking or versatile shelving systems, our expert team will help you find the ideal warehouse racking solutions to optimize your storage capacity and streamline your operations. Trust us to deliver innovative and reliable solutions for your warehouse storage requirements.

What Need To Do For Warehouse Storage Inspections, Designs And Installations

Inspections: Begin by conducting a thorough inspection of your warehouse space. Identify potential hazards, assess the condition of existing storage systems, and evaluate safety measures. Regular inspections help identify areas for improvement and ensure compliance with regulations.

Needs Assessment: Determine your specific storage requirements based on factors such as inventory type, volume, and handling equipment. Consider factors like accessibility, load capacity, and scalability to design an efficient storage solution.

Design: Work with a professional storage solutions provider or an experienced engineer to create a warehouse layout that maximizes space utilization, promotes workflow efficiency, and ensures safety. The design should include the placement of shelving, racking, and other storage systems.

Installation: Once the design is finalized, collaborate with a qualified installation team to set up the storage systems properly. Ensure that the installation is carried out according to safety guidelines and industry standards.

By following these steps, you can ensure effective storage and warehousing services, such as, warehouse storage inspections, designs, and installations that optimize your space, enhance operational efficiency, and maintain a safe working environment.

Most Required Storage Equipments

E-commerce storage solutions

Cold store racking

Warehouse storage equipment

Mezzanine shelf

Mezzanine floor racking

Wide span metal shelving

English

English