Are you worrying about the limited storage area of the warehouse? Do you want to reduce the rental cost by increasing the storage area? China warehouse racking manufacturer Maobang Group provides competitive prices and high-end quality for types of warehouse racking and shelving for sale. Our warehouse storage equipments include bulk pallet racking, selective racks, wide span shelving racks, drive in racks, mezzanine work platform, cantilever racks, boltless metal racks, steel pallets, wire mesh containers, stacking pallet cages, and so on. These warehouse racking and shelving products can realize your wishes.

Maobang warehouse storage racking factory specializes in warehouse storage rack systems, who aim to help you maximize storage density horizontally and vertically in your warehouse space. As a warehouse racking manufacturer, we have a wide range of warehouse storage shelving systems and warehouse shelving solutions that will re-create your warehouse. A right warehouse storage system should consider type of goods and warehouse, material handling equipment, fire exits and stock keeping unit. With the right storage rack system, you can store more items and increase security. Whether you need high racks or more floor space, we have a set of warehouse shelving systems for you to choose that best suit your warehouse space.

Different kinds of warehouse racking system will provide different storage capacity. If you put light duty goods on the shelf directly, you can choose long span racking system.

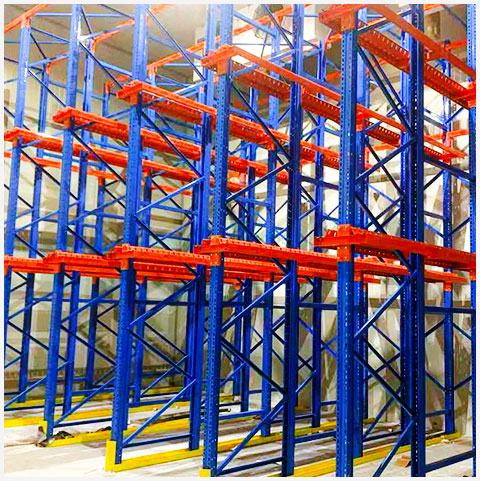

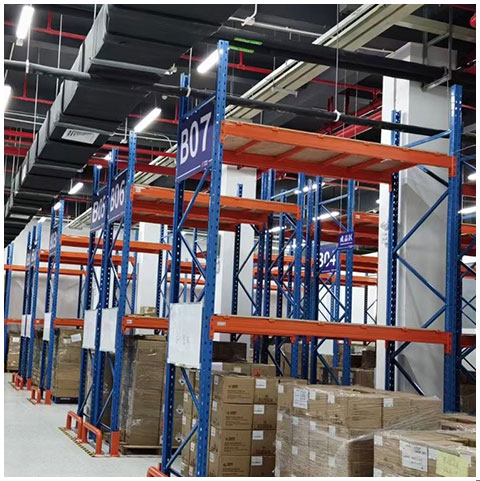

If your warehouse is high and want to store more goods, you can choose the heavy duty racking system, such as selective pallet racking, drive in racking and racking supported mezzanine floor.

If you are not sure which racking system would be suitable, our engineers will help you to design that meets your needs. Our passion is to help you find a warehouse racking system that can increase efficiency and flexibility to meet your business needs.

Designing an efficient warehouse rack layout is crucial for optimizing storage and warehousing services. Start by assessing the available space and inventory requirements. Consider factors such as product dimensions, weight, and turnover rate. Next, determine the types of warehouse racking systems suitable for your needs, such as selective, drive-in, or push-back racks. Utilize a warehouse shelving design that maximizes vertical space while allowing for smooth movement of goods.

During installation, follow manufacturer guidelines to ensure structural integrity and stability. Engage professionals experienced in warehouse racking systems installation to guarantee proper assembly and adherence to safety regulations. Regular warehouse racking inspection is essential for identifying potential hazards, ensuring load capacity adherence, and preventing accidents. Inspections should cover rack stability, anchor integrity, and beam and upright conditions. Implement a routine inspection schedule to address any maintenance or repair needs promptly.

Remember, a well-designed warehouse rack layout enhances operational efficiency, minimizes handling time, and maximizes storage capacity. It is essential to prioritize safety and compliance throughout the process to create a secure and productive warehousing environment.

For storing long materials, ring materials, plates, pipes and irregular goods, cantilever shelves are the best choice.

If it is a larger roll of cloth, it can be placed directly on the pallet, because the cloth is a relatively heavy cargo, because the weight has made it impossible to easily slip off.

The drive in racks can be used for forklifts (or unmanned trucks with forks) to enter the channel to access the goods, which is suitable for the storage of small types and large batches of goods.

The wide-span shelf is a very economical, practical and convenient warehouse shelf.

Custom warehouse shelves - take loft shelves, for example, loft shelves do not require much attention to classification.

The customer's evaluation of us is professional, has high production efficiency, and has rich installation experience.

The design of the shelf should also consider the bearing capacity, and choose a better material, to ensure that will not be crushed, or placed too long and rust and so on.

We recommended that customers add a sign on the heavy-duty racking system so that the pickers can quickly and easily find the goods in different time periods.

After the second modification, the finished product finally matched the customer's needs 100%.

Racking supported mezzanine system is a simple racking shelf that makes full use of the upper space of the warehouse.